CEMEN TECH VOLUMETRIC MIXERS

CONTROL YOUR CONCRETE.

GET CONCRETE WHEN AND WHERE YOU NEED IT WITH MOBILE CONCRETE MIXERS.

Why Choose a Volumetric Concrete Mixer?

Want fresh concrete every time? Our volumetric concrete mixers let you mix concrete right at the job site. You can change the mix easily! No more wasted concrete. Our mobile concrete mixers save you time and money. Do more jobs without going back to the plant. Get the concrete you need, when you need it.

Save up to

40%

in MATERIAL COSTS

- Save money on materials

- Make your own schedule

- Get the right amount of concrete

- Control the quality of your concrete

- Manage your fleet and budget

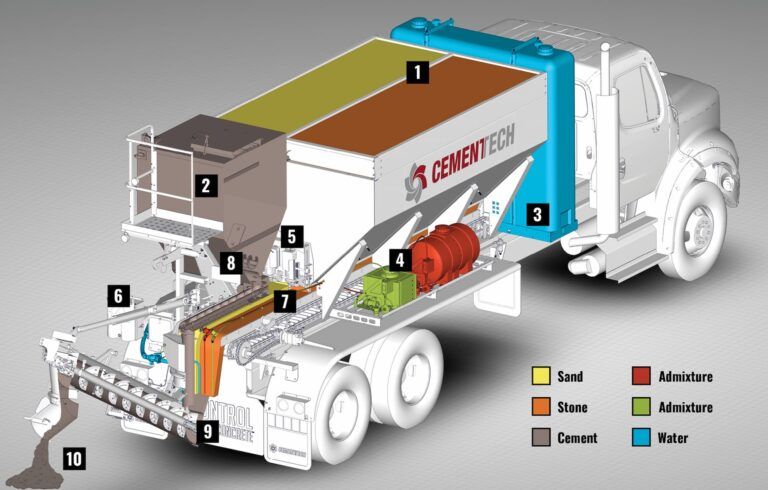

HOW IT WORKS

Cemen tech's mobile concrete mixers make fresh concrete on-site, saving time and money.

Want to make concrete work easier? Cemen Tech volumetric concrete mixers let you mix concrete right at your work site. This means you get exactly the amount you need, when you need it. It’s a better way to work compared to traditional drum mixers.

How Volumetric Concrete Mixing Works

Cemen Tech mobile concrete mixers keep the concrete materials separate until you’re ready to mix. This makes sure you always get fresh, strong concrete. You can make exactly what you need, when and where you need it, and without any waste. It’s a smarter, more cost-effective way to mix concrete—saving you time and giving you total control over your projects. Compared to traditional drum mixers, our solution offers better versatility and a stronger return on investment.

EQUIPMENT

C-SERIES

C-Series Mixers help you get the job done faster and with less waste. It’s eco-friendly, using less water and creating less carbon than traditional drum mixers.

CEMENT SILO

Cement silos enhance productivity by keeping bulk cement readily available for continuous concrete production. By enabling bulk cement purchases, cement silos help reduce material costs and minimize downtime, keeping your projects on track.

C60

SPEC SHEET

SPEC SHEETThe Cemen Tech C60 is the world’s best-selling, fully-automated volumetric concrete mixer. It’s designed to make your job easier by batching, mixing, pouring, and tracking concrete in one simple unit. With the press of a button, you can start or stop the mix, ensuring fresh concrete every time. Save money and get consistent results with pre-programmed mix designs that deliver high-quality concrete on demand.

Cement Bin Capacity

115 – 140 cu ft (3.26 – 3.96 m³)

Water Tank

510 gal (1930 L)

Production Rate

60 cu yd/hr (45.87 m³/hr)

Carrying Capacity

8-10 cu yard (6.12 – 7.65 m³)

C60T

SPEC SHEET

SPEC SHEETThe Cemen Tech C60T is the trailer-mounted version of the world’s best-selling, fully-automated volumetric concrete mixer, the C60. Ideal for projects like new housing developments, bridge work, and remote locations. Simply pull up and easily discharge flowable fill into holes or other designated areas, making it perfect for utility market applications. Ready-mix companies looking to expand into new markets can also leverage the C60T to feed barrel trucks, further increasing its versatility.

Carrying Capacity

10 cu yd (7.65 m³)

Cement Bin Capacity

115 cu ft (3.26 m³)

Water Tank

510 gal (1930 L)

Production Rate

60 cu yd/hr (45.87 m³/hr)

CD2

SPEC SHEET

SPEC SHEETThe CD2 is the next-generation volumetric mixer in the C Series lineup. Fully automated with a split bin for cement and supplementary materials like fly ash, it simplifies meeting Department of Transportation (DOT) standards. With real-time ingredient mixing, the CD2 boosts versatility and performance, allowing you to create durable concrete mixes on-site without extra equipment.

Cement Bin Capacity

115 cu ft (3.26 m³)

Water Tank

510 gal (1930 L)

Carrying Capacity

8-10 cu yard (6.12 – 7.65 m³)

SCM Bin

80 cu ft (2.27 m³)

CT-200LP

SPEC SHEET

SPEC SHEETThe CT-200LP low-profile silo provides a compact, portable solution for storing bulk cement. Ideal for flexible job sites, ensuring cement is always ready for immediate use. Designed to reduce downtime and boost productivity, the CT-200LP keeps your concrete production running efficiently and on schedule.

Bag House Capacity

150/330 sq ft (14/31 m²)

Silo Capacity

800 cu ft (22.65 m³)

Motor

Gas or electric

CT-375LP

SPEC SHEET

SPEC SHEETExcellent solution for high-capacity bulk cement storage, this silo is portable and easy to move between job sites. The CT-375LP reduces downtime and optimizes your concrete production, keeping projects on track.

Empty Weight

15,000 lb (6804 kg)

Silo Capacity

1500 cu ft (42.48 m³)

Bag House Capacity

330 sq ft (31 m²)

Motor

Electric

CT-270

SPEC SHEET

SPEC SHEETDesigned for both stationary and portable setups, helping you manage your cement supply effectively and reduce downtime. Its compact design maximizes space, making it an ideal solution for operations with limited ground space.

Silo Capacity

1080 cu ft (30.58 m³)

Bag House Capacity

150/330 sq ft (14/31 m²)

Empty Weight

8,500 lb (3856 kg)

Motor

Gas or electric

CT-350

SPEC SHEET

SPEC SHEETDesigned for efficient bulk cement storage, this model supports both stationary and portable setups, optimizing space and reducing downtime. The CT-350 ensures you have a reliable supply of cement for continuous production, enhancing your operation’s efficiency.

Empty Weight

10,000 lb (4536 kg)

Silo Capacity

1400 cu ft (39.64 m³)

Bag House Capacity

150/330 sq ft (14/31 m²)

Motor

Gas or electric

CT-450

SPEC SHEET

SPEC SHEETThis high-capacity silo is designed for efficient bulk cement storage, ideal for both stationary and portable setups. The CT-450 maximizes ground space and ensures a steady supply of cement, reducing downtime and enhancing productivity for large-scale concrete operations.

Empty Weight

12,000 lb (5443 kg)

Silo Capacity

1800 cu ft (50.97 m³)

Bag House Capacity

330 sq ft (31 m²)

Motor

Electric

G-SERIES

Built for the demands of gunite and shotcrete applications, the G Series gunite mixer from Cemen This mixer is perfect for producing high-strength, low-permeability material that stands the test of time.

M-SERIES

Whether you’re handling general concrete projects, municipalities, or utilities, the M Series delivers the flexibility and control you need in a compact footprint.

SCD-SERIES

This SCD Series mixers offer the flexibility to produce a variety of concrete mix designs, allowing you to handle a wider range of jobs with ease.

C30X

SPEC SHEET

SPEC SHEETThe GX30 gunite mixer is designed for efficiency and durability, making it ideal for high-strength, low-permeability gunite and shotcrete applications. With a 12 cubic yard carrying capacity and a production rate of 30 yards per hour, this mixer delivers consistent, high-quality material. Its precise volumetric technology ensures accurate measurements, helping you save time and money while running continuously without waiting on ready-mix trucks.

Cement Bin Capacity

115 cu ft (3.26 m³)

Carrying Capacity

12 cu yard (9.17 m³)

M15T

SPEC SHEET

SPEC SHEETDesigned for flexibility and durability, this mixer is perfect for smaller to medium-sized jobs requiring precise concrete mix designs. Its compact size and easy operation allow you to produce fresh concrete on-demand, eliminating waste and ensuring consistent quality.

Production Rate

15 cu yd/hr ( 11.47 m³/hr)

Water Tank

260 gal (984 L)

Carrying Capacity

3 cu yd (2.29 m³)

Cement Bin Capacity

30 cu ft (0.85 m³)

M30

SPEC SHEET

SPEC SHEETThis versatile machine is perfect for medium to large jobs, delivering consistent, high-quality concrete every time. Its flexible design makes it ideal for a wide range of concrete applications, ensuring you have the right mix on every project.

Water Tank

260 – 430 gal (984 – 1628 L)

Production Rate

30 cu yd/hr (22.94 m³/hr)

Carrying Capacity

5-6 cu yd (3.82 – 4.59 m³)

Cement Bin Capacity

50 – 65 cu ft (1.42 – 1.84 m³)

M30X

SPEC SHEET

SPEC SHEETThe M30X mobile concrete mixer delivers consistent, high-quality concrete for a wide range of applications.

Water Tank

430-510 gal (1628 – 1930 L)

Carrying Capacity

8-10 cu yard (6.12 – 7.65 m³)

Cement Bin Capacity

85 – 140 cu ft (2.41 – 3.96 m³)

M60

M SERIES

M SERIESBuilt to provide superior accuracy and performance, this mixer meets the needs of large-scale operations by consistently producing fresh concrete on demand.

Water Tank

430-510 gal (1628 – 1930 L)

Production Rate

60 cu yd/hr (45.87 m³/hr)

Carrying Capacity

8-10 cu yard (6.12 – 7.65 m³)

Cement Bin Capacity

85 – 140 cu ft (2.41 – 3.96 m³)

M90

M SERIES

M SERIESThe M90 mobile concrete mixer is a high-performance unit engineered for efficiency and accuracy. This mixer delivers fresh, high-quality concrete for even the most demanding jobs, reducing waste and boosting productivity.

Carrying Capacity

10 – 12 cu yd (7.65 – 9.18 m³)

Cement Bin Capacity

115 – 140 cu ft (3.26 – 3.96 m³)

Water Tank

510 gal (1930 L)

Production Rate

90 cu yd/hr (68.81 m³/hr)

SCD2-50

SPEC SHEET

SPEC SHEETA compact and efficient solution for small to medium concrete production needs. With a 2 cubic yard capacity and real-time precision mixing, it’s ideal for smaller precast operations or jobs that require just the right amount of concrete every time. Its design eliminates waste and overages, ensuring consistent, high-quality concrete production on your schedule.

Carrying Capacity

2 cu yd (1.53 m³)

Cement Bin Capacity

30 cu ft (0.85 m³)

SCD5-50

SPEC SHEET

SPEC SHEETConsistent concrete production for medium-sized projects. With a 5 cubic yard capacity, it’s perfect for operations requiring more output without sacrificing precision or quality. Its automated volumetric mixing system ensures accurate batches and reduces waste, making concrete production both cost-effective and easy to manage.

Carrying Capacity

5 cu yd (3.82 m³)

Cement Bin Capacity

50 cu ft (1.42 m³)

SCD6-100

SPEC SHEET

SPEC SHEETEnhanced productivity for larger-scale concrete production, this stationary mixer is designed for operations needing more volume without compromising on quality or precision. This model offers a durable, compact design that ensures consistent output and easy movement when necessary.

Production Rate

30 cu yd/hr (22.94 m³/hr)

Cement Bin Capacity

50 cu ft (1.42 m³)

Carrying Capacity

6 cu yd (4.69 m³)

SCD8-150

SPEC SHEET

SPEC SHEETIdeal for large-scale operations, this stationary concrete mixer ensures accurate mixes and reduces waste, delivering top-quality concrete every time. Its durable, easy-to-move design allows for flexibility and reliability on any job site.

Production Rate

60 cu yd/hr (45.87 m³/hr)

Cement Bin Capacity

85 cu ft (2.41 m³)

SCD10-200

SPEC SHEET

SPEC SHEETA powerful solution for high-output concrete production. Built for demanding projects, this SCD stationary volumetric concrete mixer delivers consistent concrete while reducing waste and offering flexibility for various mix designs.

Carrying Capacity

10 cu yd (7.65 m³)

Cement Bin Capacity

115 cu ft (3.26 m³)

Production Rate

90 cu yd/hr (68.81 m³/hr)

CONTROL YOUR CONCRETE™

Cemen Tech designs and delivers the most accurate, technologically advanced volumetric mixers on the market. Their mixers give you control over your schedule, budget, and concrete quality. All so you can shift your focus to what matters most for your business — and get on to life outside of work. That’s something traditional barrel mixers just can’t offer.